tensile testing machine procedure

Vladan Koncar in Smart Textiles for In Situ Monitoring of Composites 2019. It is used to test the tensile strength of materials.

Solved In The Tensile Testing Of Steel The Experimental Chegg Com

To determine batch quality To determine consistency in manufacture To aid in the design process To reduce material costs and achieve lean manufacturing goals.

. If the specimen breaks due to any reason other than the tensile stress the test procedure should be discarded and a new test must be performed on a fresh specimen. Tensile testing is used to find the behavior of the material when it is subjected to a slowly applied tensile load up to when the material gets a fracture. Procedure Of Tensile Test Machine are available as part of a TestResources product line of test machine accessories that include a wide range of test fixtures high low temperature chambers furnaces tensile grips and extensometers.

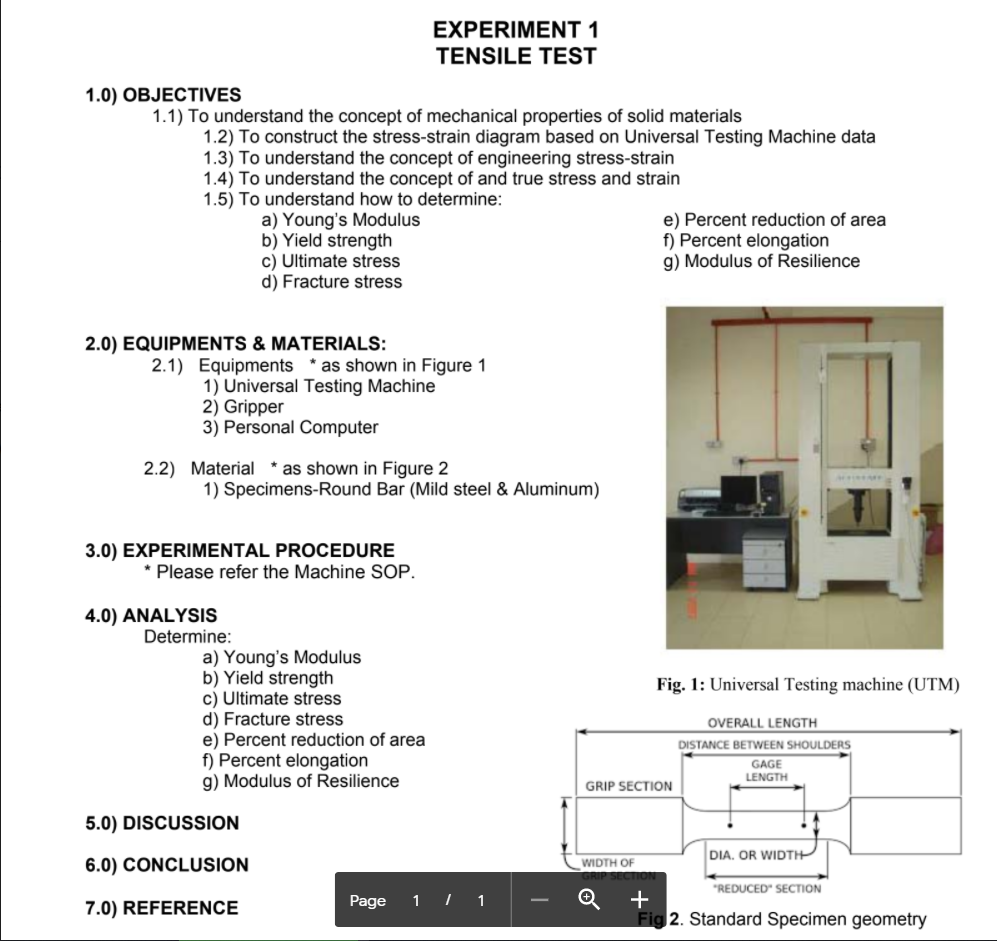

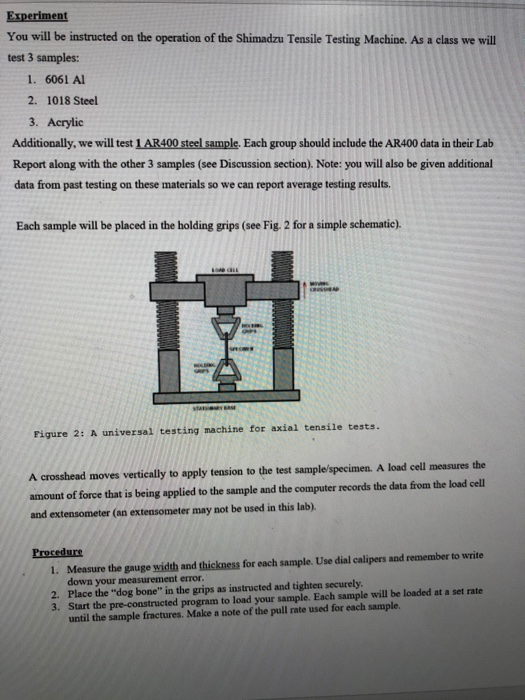

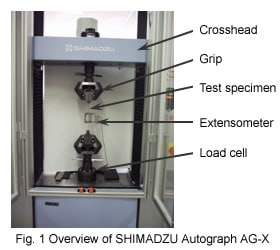

Figure 61 shows a tensile testing machine which looks similar to the one used in this lab. The testing machine provides accurate and reliable test results that are required to produce only best quality of products. A tensile tester also known as a pull tester or universal testing machine UTM is an electromechanical test system that applies a tensile pull force to a material to determine the tensile strength and deformation behavior until break.

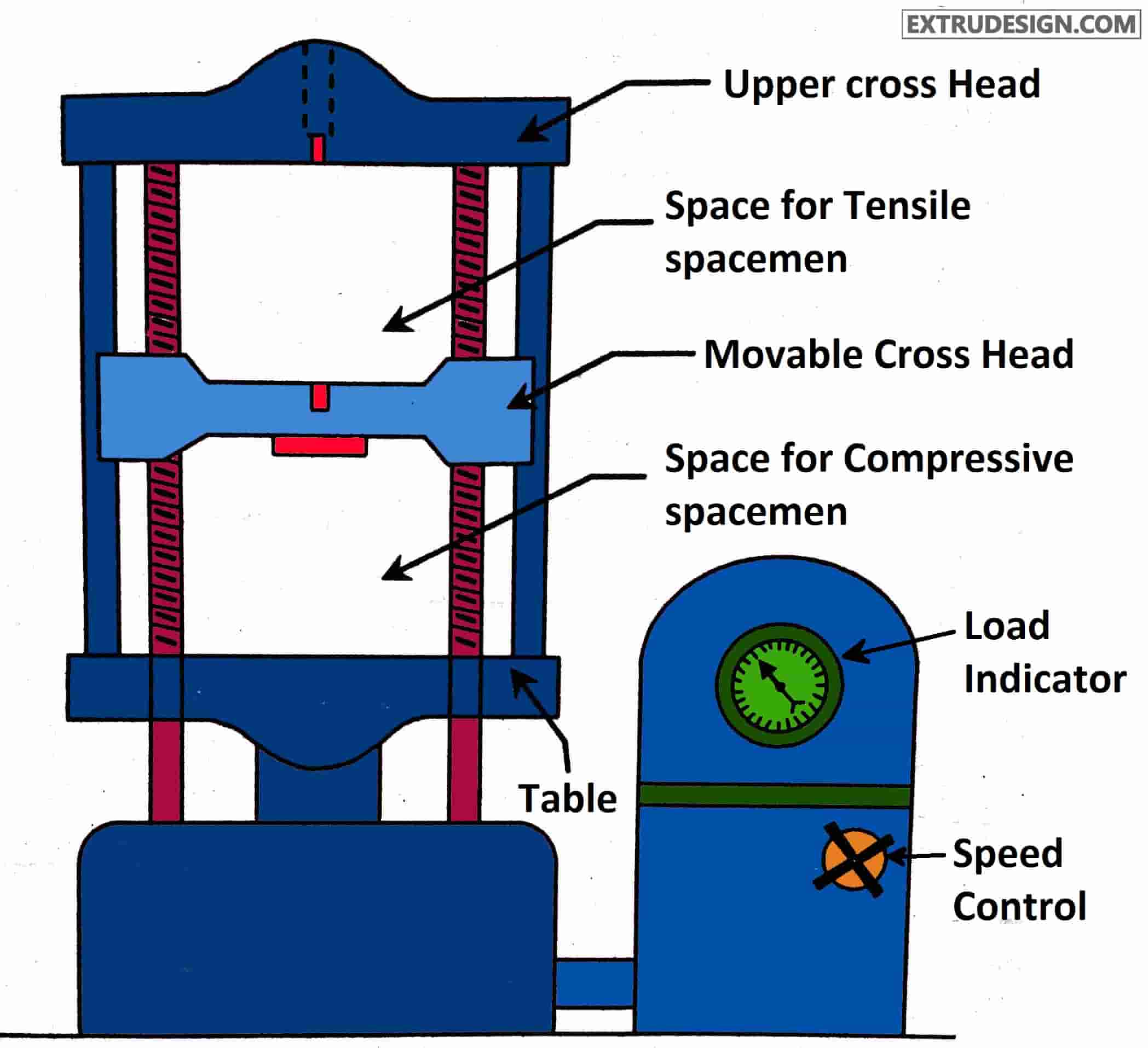

A tensile testing machine consists of a test frame that is equipped with a load cell testing software and application-specific grips and accessories such as extensometersThe type of material being tested will determine the type of accessories needed and a single machine. The procedure below uses the MTS C64206 test machine along with a pre-programmed test procedure. The grips used in the testing machine must be properly serrated so that there is no chance of slippage of the specimen.

It has enlarged ends or shoulders for gripping. These accessories can be made compatible by TestResources to match test machines supplied by other manufacturers. In the tensile test a material specimen is strained.

Tensile testing machine has been set up to make simulated stresses as alike as possible to stresses underwent by warp yarns during the weaving. Influence of the lengthening on resistance variations speed of lengthening. Universal Testing Machine Procedure for Tensile Test on Universal Testing Machine For performing the test one end of the specimen is gripped in the upper cross-head.

US1865070A 1929 which consists of loading unit and control unit as its two main units. This test is a destructive method in which a specimen of a standard shape and dimensions. Tensile testers are also known as pull testers or universal testing machines.

This test procedure creates tension on the sample which leads to sample failure or fracture. Depending on the size and shape of the material the tensile tester machine can pull at a maximum speed of 20 inches per minute. This reading is then recorded by the user to measure the maximum tensile strength of the product.

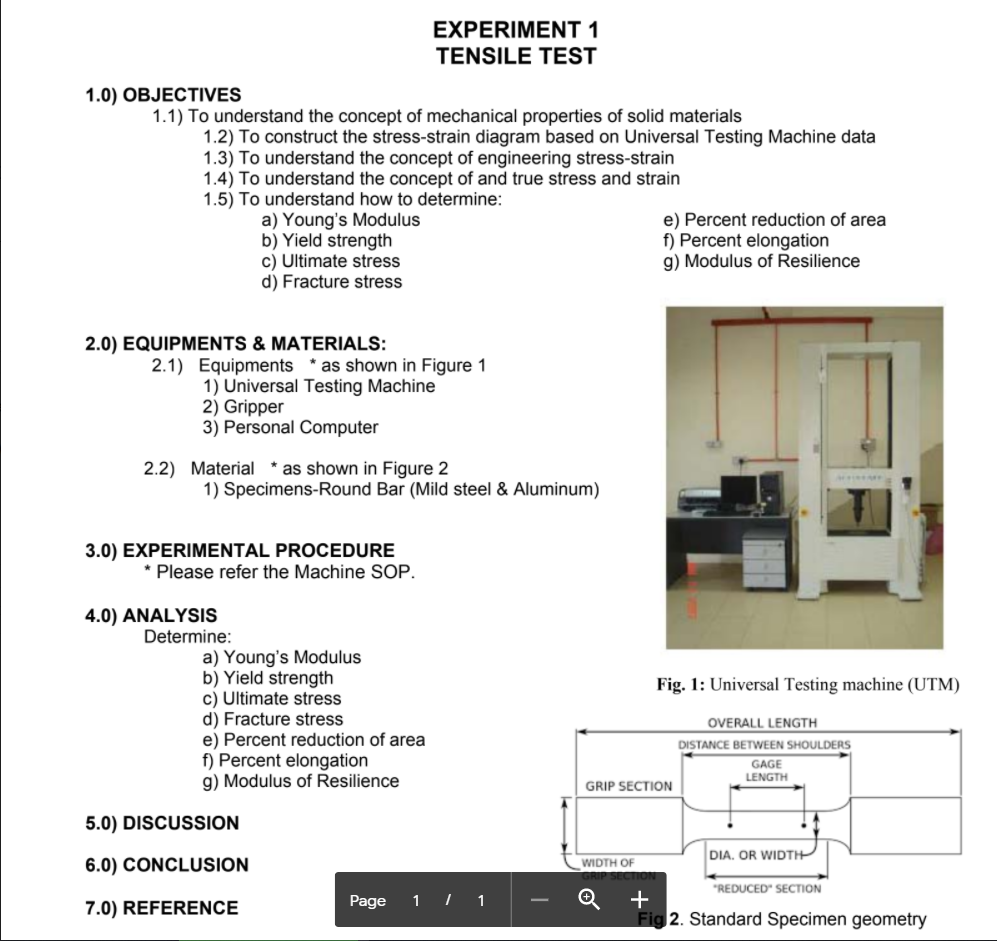

Consider the typical ten-sile specimen shown in Fig. The pre -programmed test procedure should be adequate for most re inforcing bar testing. Procedure The computerized tensile testing machine will be used to produce stress versus strain plots for several different specimens having rectangular cross sections.

To begin the tensile stress test slowly separate the tensile clamps at a constant speed. Follow Start- up Procedures. INSTRON UNIVERSAL TENSILE TESTING MACHINE.

The cross-sectional area of the gage section. The tensile testing machine to achieve. The topic of this lab is confined to the tensile property of polymers.

Debugging by the manufacturer you can also master some maintenance methods to debug it yourself. Everyone knows this well. A typical tensile testing machine consists of a load cell crosshead extensometer specimen grips electronics and a drive system.

The diameter of each specimen must be measured and recorded. Overview A tensile testing machine is used for physical strain testing procedures on standardized sample specimens. The tensile test comes under the destructive test where we apply the gradually increased load up to the material to get a fracture.

Information should be entered on the attached work sheet. These machines play a key role in any material testing laboratory. Punch marks must be made at 2 inch intervals along each sample.

The main objective of this experiment is to determine tensile strength of a material by Universal Testing Machine UTM. Benefits of Tensile Testing The data produced in a tensile test can be used in many ways including. First of all we need to know why the data of the tensile testing machine is inaccurate.

The sample is pulled apart from two ends which are fixed to the machine using tensile grips. The tensile test is conducted on UTM US Patent No. Complicate the design process include temperature and time factors.

The tensile testing would often take five minutes or less for the material to fracture. The tensile testing machine is also called the electronic tensile testing machine. The tensile test is a test method within mechanical materials testing for determination of material characteristicsDepending on the material the test is used as the standard method in accordance with the respective standard for determination of yield strength tensile strength strain at break and other material properties.

Should any alteration be needed consult with FSEL staff beforehand. These should be measured and recorded after making the punch marks. An electromechanical test machine together with contacting strain gauge and extensometer was used to perform standard tensile test procedures.

Tensile Test Specimen Figure 3. So a tensile test is a static test as a sub-classification. In the tension test a steel rod is subjected to tension load by the means of a Universal testing machine UTM.

The data is used to determine the modulus of elasticity while the specimens are examined for failure characteristics. Tension Test on Steel Rod Procedure and Results. Addresses tensile testing or reinforcing bars.

The important part of the specimen is the gage section. Tension test is performed on mild steel tor steel and high tensile steel to determine the properties like Youngs modulus ultimate strength and the percentage elongation. Tensile tests are performed on tensile testing machines also known as universal testing machines.

Following parameters have been tested. Testing Machines Tensile Specimens. 4141 Yarns testing procedure.

Universal Testing Machine Construction And Working Principle

Tensile Testing An Overview Sciencedirect Topics

What Causes Measurement Errors In Material Testing

![]()

Tensile Strength Of Concrete Test Split Cylinder Test Of Concrete Tensile Strength Test Procedure

Universal Testing Machine Procedure And Calculation Tensile Strength Yield Test Youtube

How To Configure A Tensile Test Machine In Three Steps

Tensile Test Specimen Figure 3 Universal Testing Machine Procedure For Download Scientific Diagram

Tensile Test Specimen Figure 3 Universal Testing Machine Procedure For Download Scientific Diagram

Solved Experiment 1 Tensile Test 1 0 Objectives 1 1 To Chegg Com

A Tensile Test Is A Universal Test Where A Sample Is Chegg Com

Tensile Test For Steel Material With High Accuracy Strain Control Shimadzu Shimadzu Corporation

Tensile Test Specimen Figure 3 Universal Testing Machine Procedure For Download Scientific Diagram

Tension Testing Tensile Testing Admet

Universal Testing Machine Utm Working Explained Tensile Test Along With Stress Strain Curve Youtube

Tensile Test Tensile Strength Or Tension Test Lab Experiment

Tensile Test On Utm Machine How To Perform Tensile Test Tensile Test Full Detail ह न द Youtube

Schematic Diagram Of Tensile Testing Machine Download Scientific Diagram